Efficient extraction of the air that enters the cockpit from the vents has been considered in many glider designs over the years but only recently has it been investigated further to understand the impact on glider performance. Most gliders have openings at the base of the rear of the fin to try and allow the air to exit the fuselage efficiently. Poor extraction leads to pressurisation of the cockpit causing air to escape around the canopy and through the control surfaces of poorly sealed gliders.

Glaser Dirks have designed and tested the “Mandl Air Extractor”, (http://www.dg-flugzeugbau.de/index.php?id=mandl-absaugung-e) as a retrofit option to some of the LS series of gliders. The extractor is fitted on the underside of the fuselage, behind the wheel. Results show a reduction in cockpit pressure, improved effectiveness of the cockpit vent and a slight performance increase.

Jonker Sailplanes have analysed the issue using Computational Fluid Dynamics (CFD) (http://www.jonkersailplanes.co.za/airextractor.htm) to develop an air extractor that can be fitted as an optional extra on new sailplanes and retrofitted for earlier production models. The extractor is positioned on top of the fuselage in the region of the most negative pressure. Their results have also showed a reduced cockpit pressure, improved ventilation, reduced cockpit noise and a perceptible performance improvement.

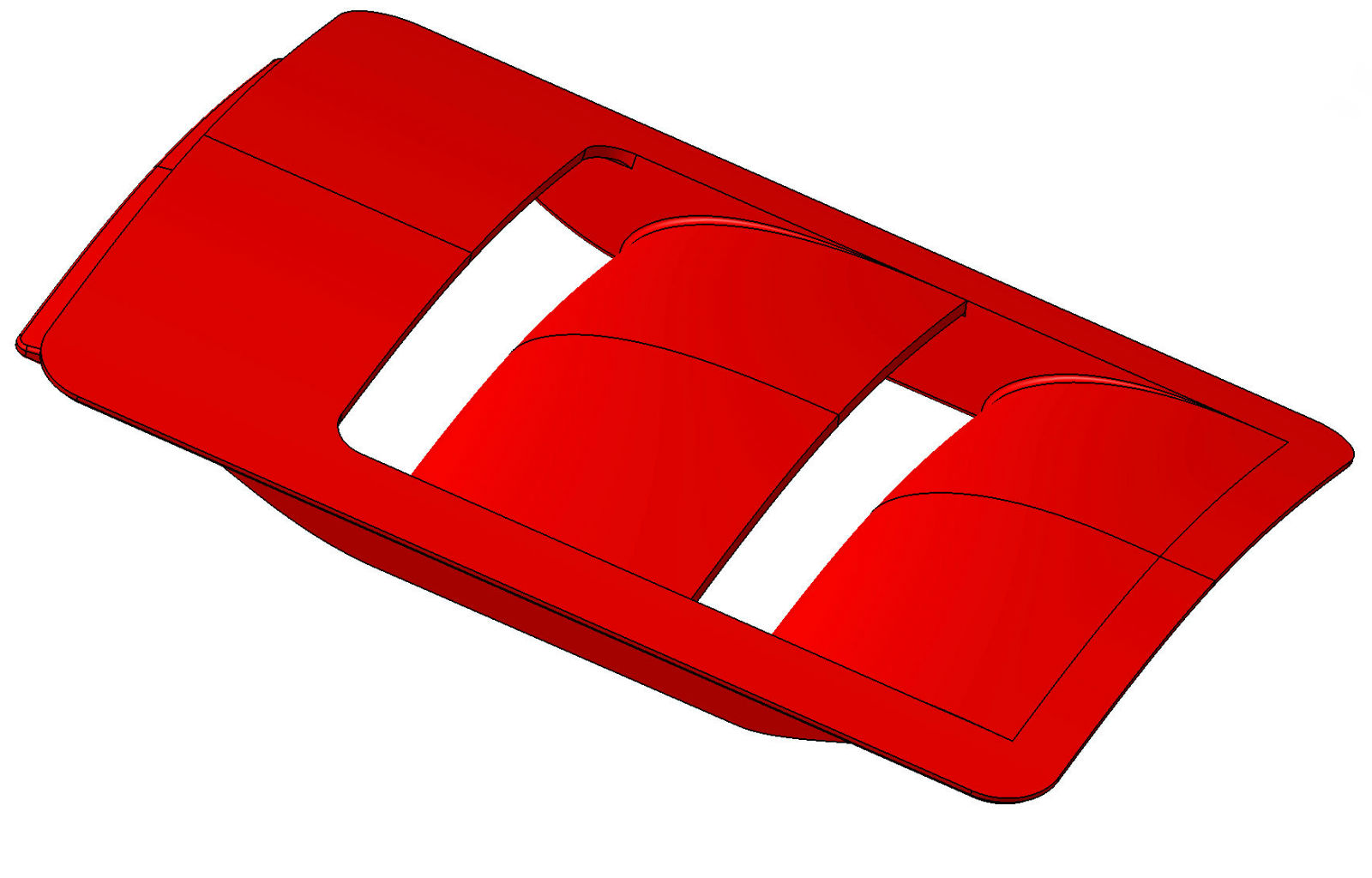

The Air Extractors developed by LJPanels have utilised Formula One CFD and Aerodynamics expertise and tools to create a complex shaped double aerofoil louvre vent system that fits into the existing inspection panel aperture on the fuselage so no structural modifications are required. The Air Extractor has a forward fixing that doubles as a surface to ensure the air is extracted correctly.

As can be seen from the CFD results at http://www.lcs-fast.com/glider/, the air efficiently exits the fuselage and successfully reattaches to the external flow along the fuselage.

A prototype duct has been flying in the UK for over two years. Below is a review from the owner - Pete Stratten, CEO at British Gliding Association.

"The vent appears to help air flow out of the fuselage in an orderly fashion (!) along with the fuselage rear vent hole (which is probably restricted by rudder Mylar sealing). The net result should be less air flowing out of the airframe where it shouldn't. Which hopefully keeps total drag at a level that the designer expected it to be. I have no complaints about the glide performance of my ASW20."

Due to the complex nature of this design, the Air Extractor is made out of a structural rapid prototyping material that allows for a lightweight and aerodynamically superior part.

ASW19 & ASW20 Air Extraction Duct