LJPanels is a new company providing a range of glider maintenance and repair services. In additon to the standard maintenance and repair work, the company has considerable experience in the design, manufacture, installation and testing of high quality, bespoke aircraft instrument panels. The aim of LJPanels is to offer customers a variety of options to update their aircraft instrument panels and wiring allowing the latest instrument technology to be installed at the best cost and time efficiency.

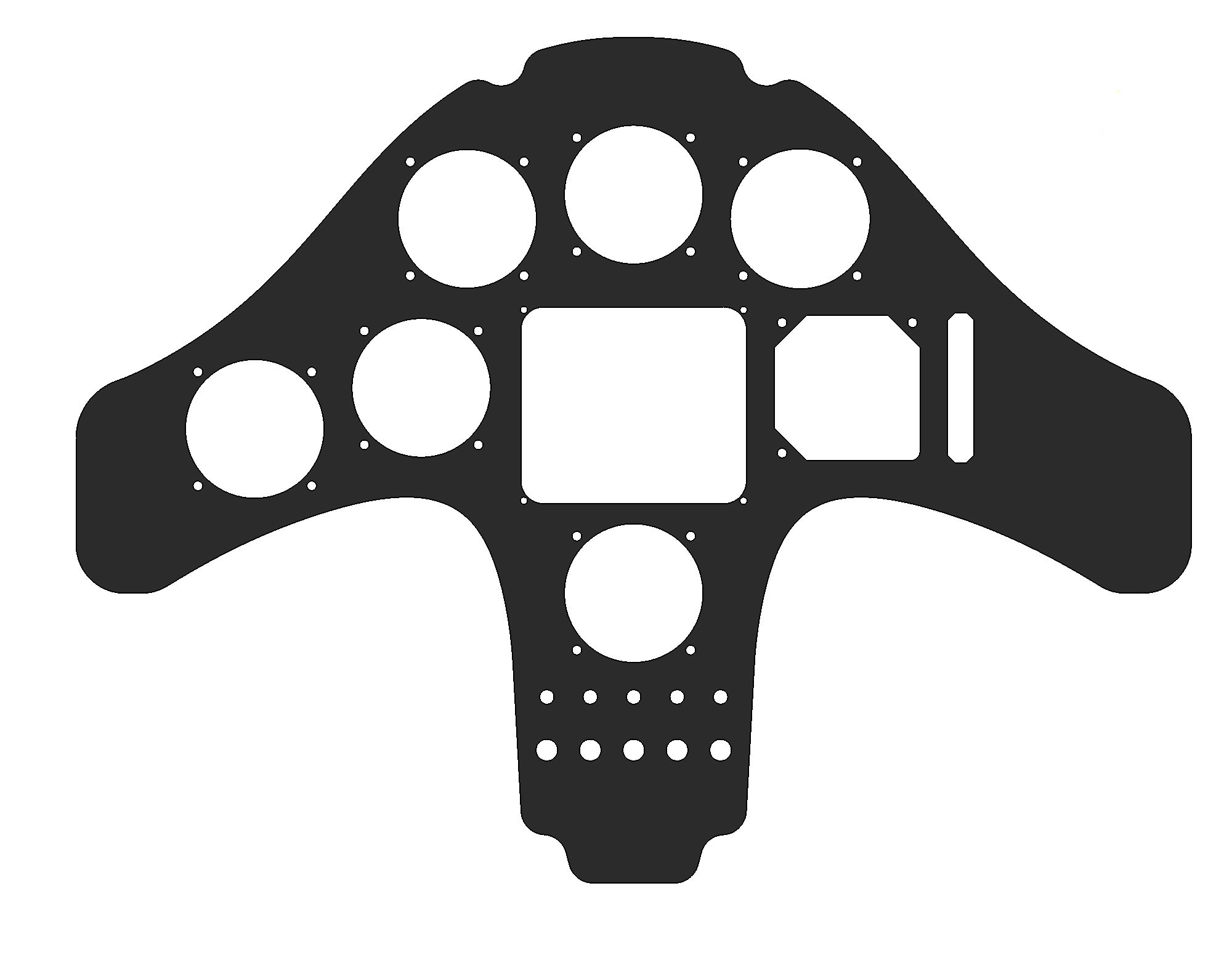

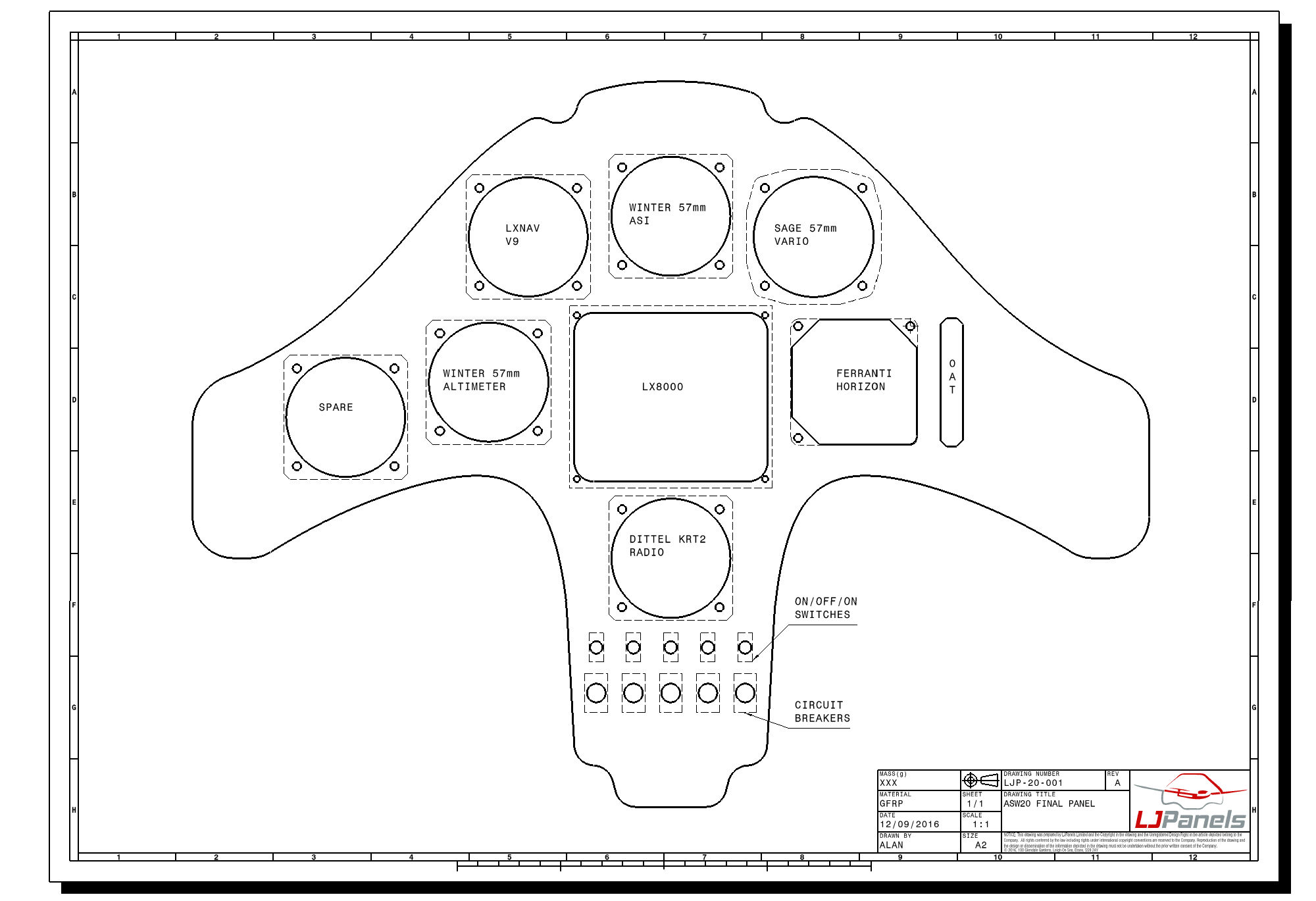

Recent years has seen the introduction of modern glass technology at a reasonable price for many aircraft owners. The non-standard shapes and sizes of these instruments means that a simple swap is not often possible. The various shapes and sizes of the new instruments to be installed, often in small panels, place a huge emphasis in the careful design of the panel before any holes are cut. The use of an accurate template of the panel created in a 3D CAD package allows the customer to be closely involved in the design process with the ability to review drawings and lightweight models before the first precision cut is made.

Additional accessories, such as flap sensors, need to be carefully installed to ensure there are no potential airworthiness issues and LJPanels has developed various techniques to allow them to be installed quickly and safely.

LJPanels can provide a full range of instrument and avionics services from simply designing a layout for the customer to cut their own panel, through to building a ‘plug and play’, low maintenance panel and to rewire with aerospace / F1 grade wiring. This could incorporate high quality quick release connectors that allow easy removal for winter storage.